Materials Testing

Asphalt & Bitumen

We are ready to provide you with advice or a quote.

Send us an enquiry here or call 066 299 1985.

Our accredited facilities can perform full Marshall control testing and a wide range of asphalt, bitumen and road-readiness services, according to any standard you require.

Asphalt & Bitumen

SERVICE OFFERING

01

Marshall Stability, Flow and Quotient

Used to determine the stability and flow of compacted asphalt briquettes with an electronic plotter.

02

Bulk density and void content

Known as BRD, this test determines the density of the hot mix asphalt mix after compaction.

03

Gyratory Compaction

Compaction of asphalt samples to target mixture or void content to determine mixture compatibility and design properties.

04

Walking profilometer

Evaluate the surface condition of pavement. Measures surface roughness, texture and transition irregularities and surface rutting.

05

Falling Weight Deflectometer (FWD)

The most practical system to accurately measuring pavement’s deflection response when subject to a dynamic load.

06

International Roughness Index (IRI)

Measure surface roughness, texture and rutting to calculate ride comfort, surface friction and noise generation.

07

Model Mobile Load Simulator (MMLS)

One of 13 world wide, this allows us to simulate traffic, moisture and temperature effects on a pavement layer, recreating real-life stresses.

08

Hamburg Abrasion Testing

Samples can be tested to determine their susceptibility to rutting and moisture against different load, temperature and moisture settings.

09

Rolling straight edge

Used to determine the rideability of a specific road surface area and measure the transition between where processed sections join.

10

Theoretical Maximum Specific Gravity

A hot mix asphalt sample is placed into a pycnometer and a vacuum pump removes all air from the sample to determine the mix density.

11

Soluble binder content and particle size analysis

Used to determine the percentage of binder in the hot mix asphalt sample. Sample is washed and processed to ensure no aggregate material is lost.

12

Bitumen content of asphalt mix

Used to determine the percentage of binder in the hot mix asphalt sample. Final weight is compared to the starting weight to determine loss.

13

Binder content of mixtures

Used to accurately determine the net bitumen content of a slurry mixture.

14

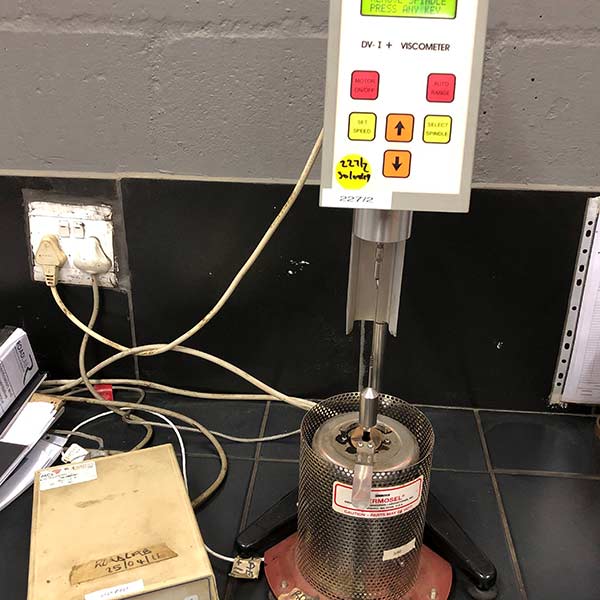

Low- temperature and dynamic viscosity

Used to determine the shear-rate and apparent viscosity of bitumen.

15

Rolling thin film oven

Simulating the hardening properties of bituminous binders during mixing, transportation and compaction.

16

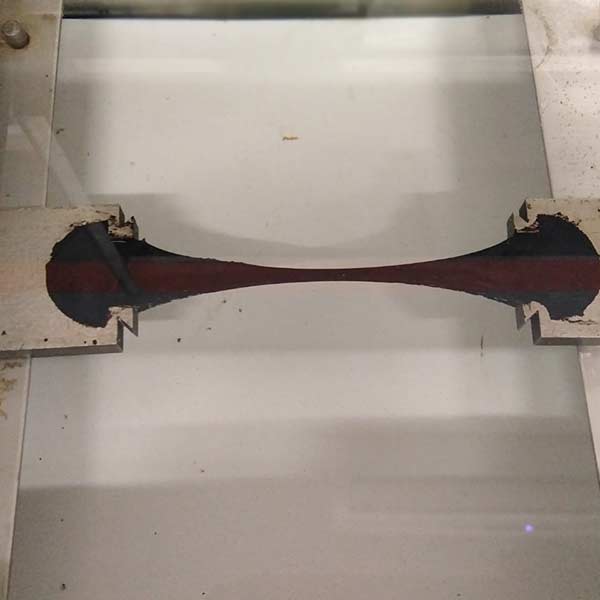

Elastic recovery

This test method is used to determine the elastic properties of a polymer modified bituminous binder.

17

Ball penetration and resilience

The penetration of a standard ball into bitumen-rubber measures the relative hardness or consistency of bitumen rubber blends.

18

Compression recovery

Measures the rubber crumbs' contribution to a bitumen rubber blend’s ability to return to its original shape after compression.

19

Flow test

This test is used to measure the flow properties of bitumen at high temperatures.

20

Ball penetration test

Used to simulate the embedment of stone chips that occurs during construction and under traffic loading.

21

Texture depth measurement

This test is used to determine the texture of a road surface, also known as the roughness.

22

Marvil test

The permeability of a bituminous layer indirectly indicates the material’s susceptibility to the ingress of water.

23

Certification of a binder distributor

Certification of a binder distributor, validation of binder distributor dipstick, power and speed indicator test, pump system performance, and transverse distribution.

24

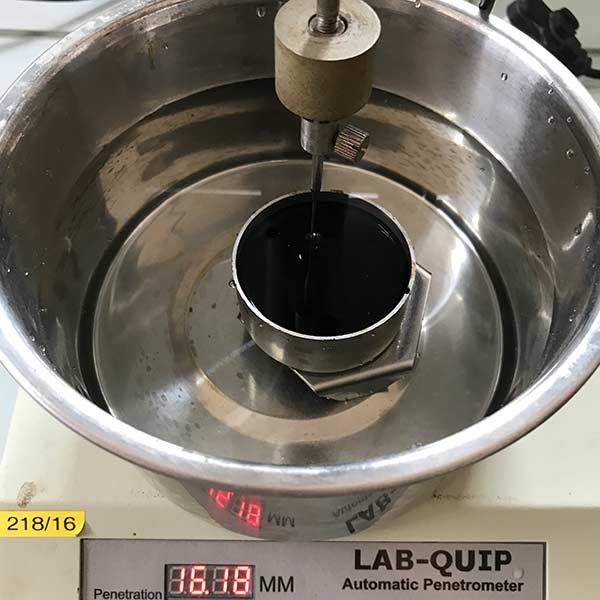

Penetration of bituminous materials

Used as a measure of the consistency of bituminous materials. Higher values of penetration indicate softer consistency.

25

Softening point of bitumen

Useful in the classification of bitumen as one element in establishing the uniformity of receiving shipments of binder.

26

Water content

Measures the water present in the emulsified asphalt as distinguished from either bitumen or petroleum solvent.