MATERIALS TESTING

AGGREGATE

We are ready to provide you advice or a quote.

Send us an enquiry here or call 066 299 1985.

Our accredited facilities perform all manner of aggregate testing, including gradation, fines content and plasticity according to any standard you require.

AGGREGATE

SERVICE OFFERING

01

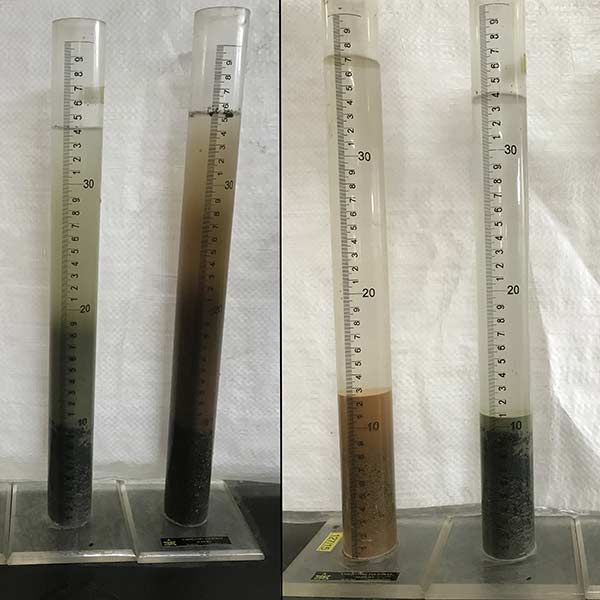

Particle Size Analysis

Also known as sieve analysis, this test is done to determine if the aggregates are fit for purpose.

02

Average Least Dimension (ALD)

The arithmetic mean of all the measured least dimensions of the aggregate particles measured.

03

Flakiness Index

A measurement of the flatness of an aggregate, affecting the performance of road surfacing aggregates and the workability of concrete.

04

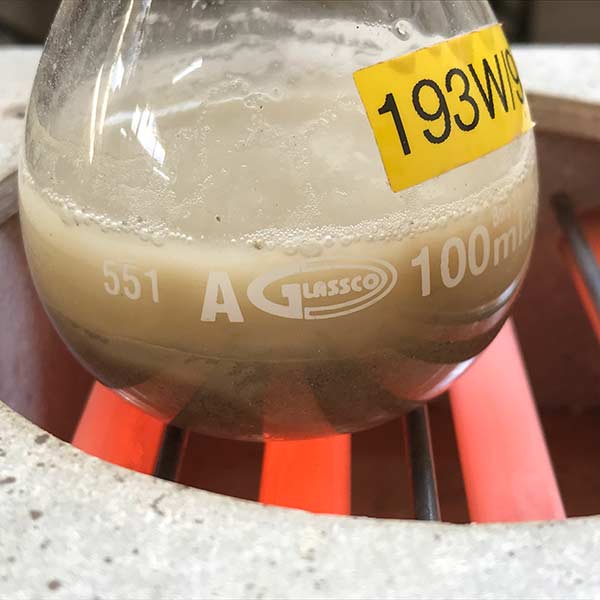

Sand Equivalent

Reveals relative proportions of dust or clay-like materials, used to assess the quality of fine aggregate used in concrete and asphalt.

05

ACV and 10% FACT

Determines the particle strength of aggregate for concrete, surfacing (chips) and asphalt, as well as for crushed stone base.

06

Polished Stone Value (PSV)

Simulates the resistance of aggregate to the polishing action of vehicle tyres under conditions similar to those occurring on a road surface.

07

Bulk Density

Determine the relative compaction of a crushed stone base and mix design procedures of concrete and asphalt where volumetric and water absorption properties are required.

08

Apparent Density

This test is used to determine the apparent density of crushed stone base. The results are used to determine compliance of the density with applicable specifications.