Materials testing

Specialised testing

WE NEED A HEADING FOR HERE

WE NEED THE DESCRIPTION FOR HERE

Specialised Testing

TESTING PROCEDURE

01

Gyratory Compactor

Gyratory compaction is used for precision compaction of asphalt samples to a specific target mixture or void content. Clients can get more precise readings of their samples to determine the mixture compatibility and mixture design properties.

02

Hamburg Abrasion Testing

Specimens prepared in the laboratory or cores from field samples can be tested under simulated conditions in the laboratory to determine their susceptibility to rutting and moisture against different load, temperature and moisture settings.

03

Polish Stone Value (PSV)

PSV is to simulate the resistance of the aggregate to the polishing action of vehicle tyres under conditions similar to those occurring on a road surface. The PSV of an aggregate is a measure of the resistance of an aggregate to polishing. Aggregates that retain a significant micro texture after polishing are the aggregates that give good resistance to abrasion and skidding.

04

Dynamic Probe Super Heavy (DPSH)

DPSH Testing (Dynamic Probe Super Heavy) - This method consists of driving a sacrificial solid cone through soil to a depth of 20 meters, to determine a bearing pressures of soils.

05

Falling Weight Deflectometer (FWD)

The Falling Weight Deflectometer (FWD) is currently the most practical system for accurately measuring a pavement’s deflection response when it is subject to a dynamic load and is non-destructive testing technique.

06

International Roughness Index (IRI)

Pave® Prof V2.0 is a modular system that uses 3D laser sensors to measure pavement profiles for applications such as highways and runways. It measures surface roughness, texture and rutting. It is capable of real-time continuous measurements of longitudinal and transverse profiles, rut depth and macro texture. These values can be used to calculate ride comfort, surface friction and surface noise generation to international standards.

07

Walking Profilometer

Smaller scale application to measure surface roughness, texture and transition irregularities, and surface rutting.

08

Model Mobile Load Simulator (MMLS 3)

An accelerated pavement testing tool applying realistic rolling wheel contact stress, to simulate traffic, moisture and temperature on the pavement layer that results in surface rutting.

09

Concrete Crack Width Meter/Camera

Investigate cracks width on concrete structures such as walls, tunnels, bridges etc. with photographic recording - accuracy of 0.01mm.

10

Ultrasonic Pulse Velocity Meter (UPV)

Pulses of ultrasonic length waves are transmitted into concrete structures to determine the uniformity of concrete, indications of voids, estimating the depth of surface voids, checking on the effectiveness of crack repairs and severity of damage or deterioration of concrete.

11

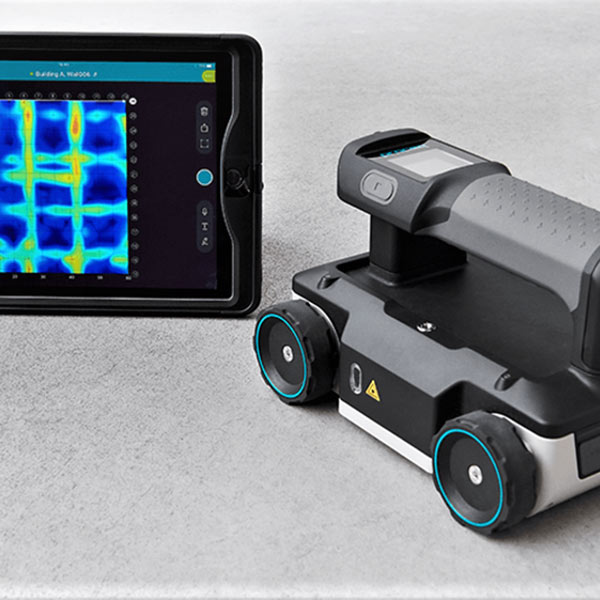

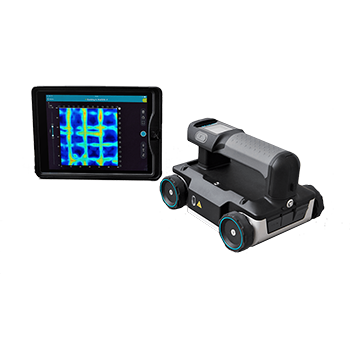

Proceq Concrete Scanning

Non-destructive testing of concrete structures using stepped frequency continuous-wave ground penetrating radar to an effective depth exceeding 700mm.